how to calculate cement sand and aggregate |concrete material calculator |calculation of concrete calculation of concrete ...

how to calculate cement sand and aggregate |concrete material calculator |calculation of concrete

calculation of concrete

In this post, we will see about How to calculate the quantity of material for RCC of any grade like

concrete material calculator

Grades of Concrete

M5 1 : 5 : 10

M7.5 1 : 4 : 8

M10 1 : 3 : 6

M15 1 : 2 : 4

M20 1 : 1.5 : 3

M30 Design Mix

M35 Design Mix

M40 Design Mix

M45 Design Mix

High Strength Concrete Grades

M50 Design Mix

M55 Design Mix

M60 Design Mix

M65 Design Mix

M70 Design Mix

M7.5 1 : 4 : 8

M10 1 : 3 : 6

M15 1 : 2 : 4

M20 1 : 1.5 : 3

Standard Grade of Concrete

M25 1 : 1 : 2M30 Design Mix

M35 Design Mix

M40 Design Mix

M45 Design Mix

High Strength Concrete Grades

M50 Design Mix

M55 Design Mix

M60 Design Mix

M65 Design Mix

M70 Design Mix

Procedure for using excel file

Step 1: calculate the total Quantity of beam or slab or column or footing.For better understanding purpose, let us take the live example of a beam of Span 10 m with a cross-section of 0.23m x 0.45m

Total Quantity of Concrete required is 10x.23x.45 =1.05cum

Step 2: Select the grade of concrete based on Environmental exposure condition

Environmental Exposure Conditions

i) Mild ConcreteBuilding surfaces are protected against weather / aggressive conditions, except in coastal areas.

ii) Moderate Concrete

the concrete surface sheltered from rain and freezing other than the mild environmental condition

iii) Severe

Outer surface Concrete exposed to severe rain, alternate wetting and drying or occasional freezing whilst wet or severe condensation. Concrete completely submerged in seawater Concrete exposed to the coastal environment

iv) Very severe

Concrete surfaces in building exposed to seawater spray, corrosive fumes or severe freezing conditions whilst wet Concrete in contact with or buried under aggressive sub-soil/groundwater

v) Extreme

The surface of members in the tidal zone of costal area Members in direct contact with liquid/ solid aggressive chemicals

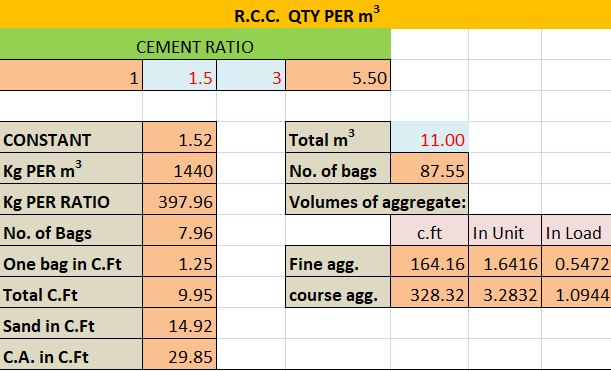

select grade and enter the ratio for eg: M20--1:1.5:3

Step 3: Enter the total quantity of concrete calculated below we will require output

Step4: output of concrete quantity, cement quantity and aggregate quantity are shown below

MANUAL CALCULATION FOR YOUR REFERENCE

Detailed analysis

on Mix ratio of concrete grade M20 = 1:1.5:3

During concreting

of structural members like footing of column or beam or slab, when we place moisture

concrete, it gets hardened after it attains its initial setting time of 30minutes.

considering similar,

it had been decided upon by Site Engineers to take a factor of safety ranging

from 1.50 to 1.57 to pledge that shrinkage.

the volume of dry

Concrete = 1.50 to 1.57 times the Volume of wet concrete.

Now designs are as

follows for 1cum of concrete work

Ratio Sum =

1+1.5+3=5.5

FOS =1.55 (we

can take any value from that ranges depending upon practicable issues)

So, the Total volume of

wet concrete required is = 1.55cum

Volume of coarse aggregate

Required = (3/5.5) x 1.55 = 0.845 m3

Volume of fine aggregate

Required = (1.5/5.5) x 1.55 = 0.422 m3

Volume of cement =

(1/5.5) x 1.55 = 0.281 m3

= 0.281 x1440 =

405kg

For 1m3 of M20

(1:1.5:3)

coarse aggregate =

0.856 m3

fine aggregate =

0.472 m3

Cement = 8.22 bag.

TNPSC AE & SSC JE CIVIL QUIZ PRACTICE

RCC

RCC-1 -Click here

RCC-2- Click here

𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘

SOM/MOS

𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘

𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘

𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘𐩘

RESIDENTIAL PLAN

#1 (40' x 80') - Click here

#2 (30' x 50') - Click here

#3 (30' x 24') - Click here

#4 (30' x 60') - Click here

#5 (30' x 70') - Click here

#6 (25' x 60') - Click here

#7 (20' x 60') - Click here

#8 (30' x 40') - Click here

COMMENTS